Summary of key areas

Energy Saving doesn’t need to be expensive. Up to 20% can be cut in many refrigeration plants through actions that require little or no investment.

In addition, improving the efficiency and reducing the load on a refrigeration plant can improve its realiability and reduce the likelihood of a breakdown.

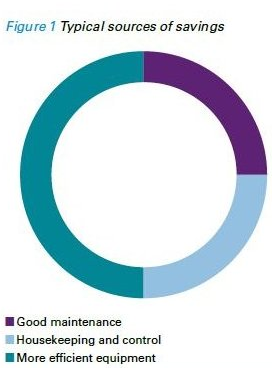

Figure 1 indicates how most organisations can save energy and money on refrigeration.

This publication provides an overview of the operation of refrigeration systems, identifies where you can make savings, and will help you to present an informed case on energy savings to key decision makers within your organisation.

Transcool (UK) Ltd are committed to environmental control and reducing carbon footprints wherever possible.

The benefits to the customer are lower running costs and reliable equipment. There is no catch.

If your refrigeration condenser is not maintained it will have to operate at a higher temperature, increasing the condensing temperature. As a result the compressors will have to do extra work. For every 1°C that the condensing temperature rises, the compressor will use between 2% and 4% more energy.

We can further improve on energy efficiency by controlling the condenser fan speed to regulate the condensing temperature, a cost effective modification.